Home » Lockout Devices » Group Lockout/Tagout

Group Lockout/Tagout

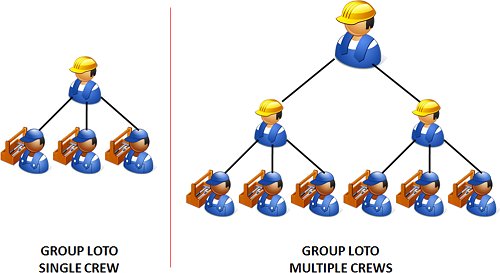

Group Lockout/Tagout is a method to provide employees a high-level of safety when multiple authorized employees need to work together to perform Maintenance or service on a piece of equipment. A key part of the process is to designate a single responsible employee who is in charge of the LOTO and is accountable for the overall LOTO procedure. Each Authorized Employee must also apply their own padlock to the points of isolation on the machine, in order to ensure that the equipment cannot be re-Energized until every employee has completed the work and is in a safe location.

Group Lockout Tagout

DEenergize offers a variety of devices to enable proper group Lockout/Tagout while complying with the requirements of OSHA 29 CFR 1910.147:

In addition to the above, make reference to the appropriate lines in other categories.

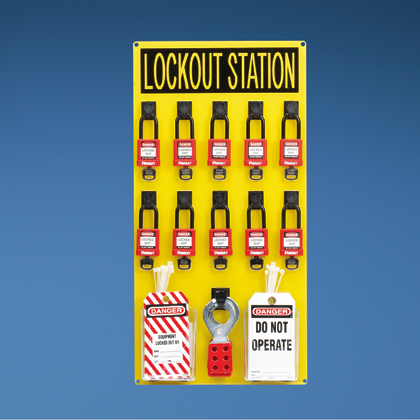

Typical Group Lockout/Tagout Station shown below.

Typical 10-person Lockout Station with Components

Lockout Services | Turnkey Programs | Lockout Procedures | Single-Source Procedures | Basic Procedures | Standard Procedures | Advanced Procedures | Custom Procedures | Energy Control Tags | Alternative Protective Measures | Minor Servicing Exception | Online Services | Lockout Audits | Corporate Standards | Lockout Training | Reference Guides | Services RFQ | DEenergizer | Lockout Devices | Electrical | Valve and Pneumatic | Accessories | Group Lockout/Tagout | Devices Index | Devices RFQ | Lockout Resources | OSHA Documentation | NIOSH Documentation | White Papers and Articles | Lockout/Tagout FAQ | Lockout/Tagout News | Lockout/Tagout Signs | Energy Source Reference | Training Material | Library | Glossary | Sitemap | About | Contact Information | Careers | Privacy Policy | Terms of Use | Legal Notice